Tool Steels

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Cutting tools for sheets up to 4 mm thickness, trimming dies, blanking dies for paper and plastics, shear blades and rotary shear blades for sheet thicknesses up to 2 mm, drawing and deep-drawing tools. Woodworking tools, stone pressing tools, pressure pads and highly wear-resistant plastic moulds, profile rolls.

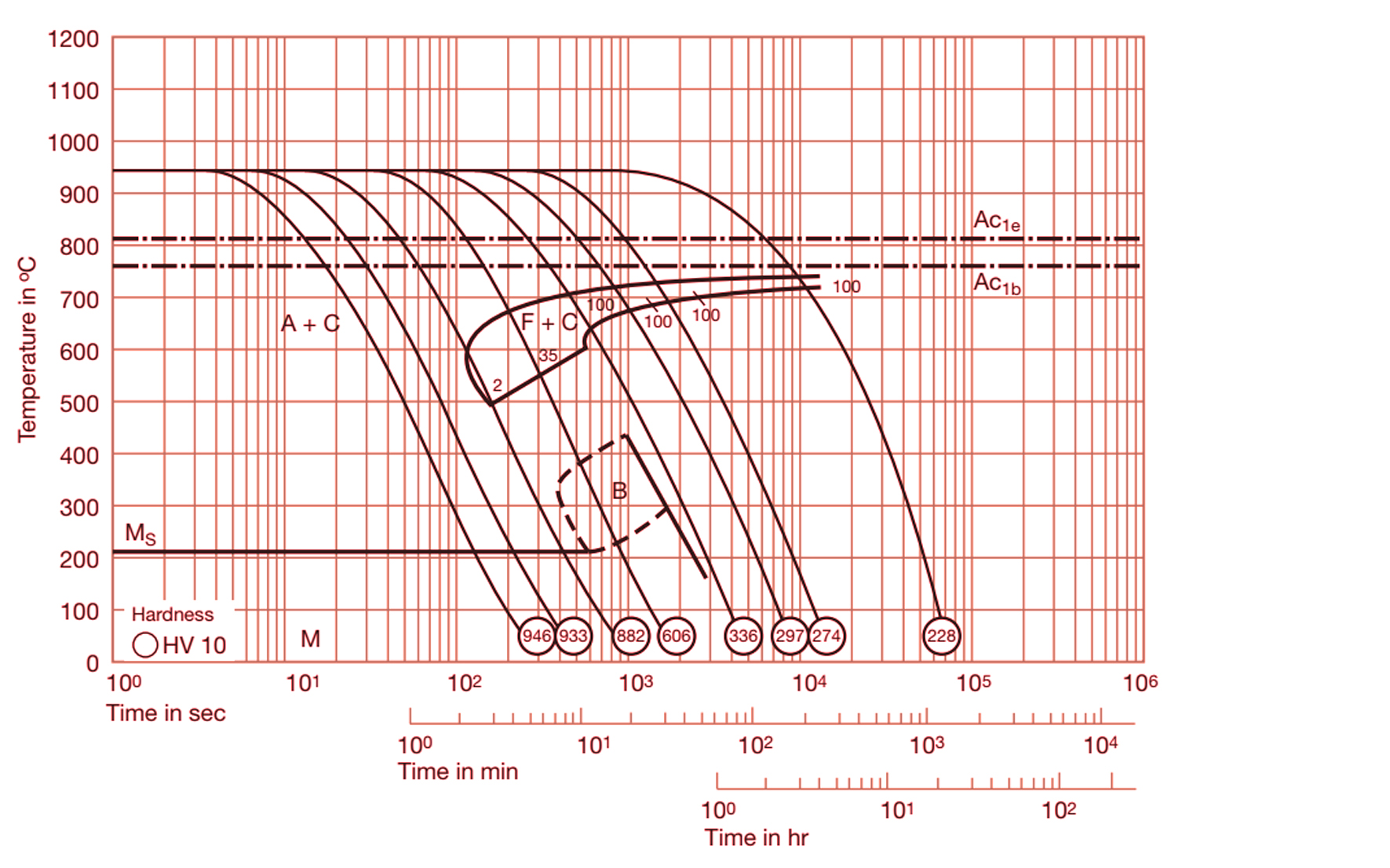

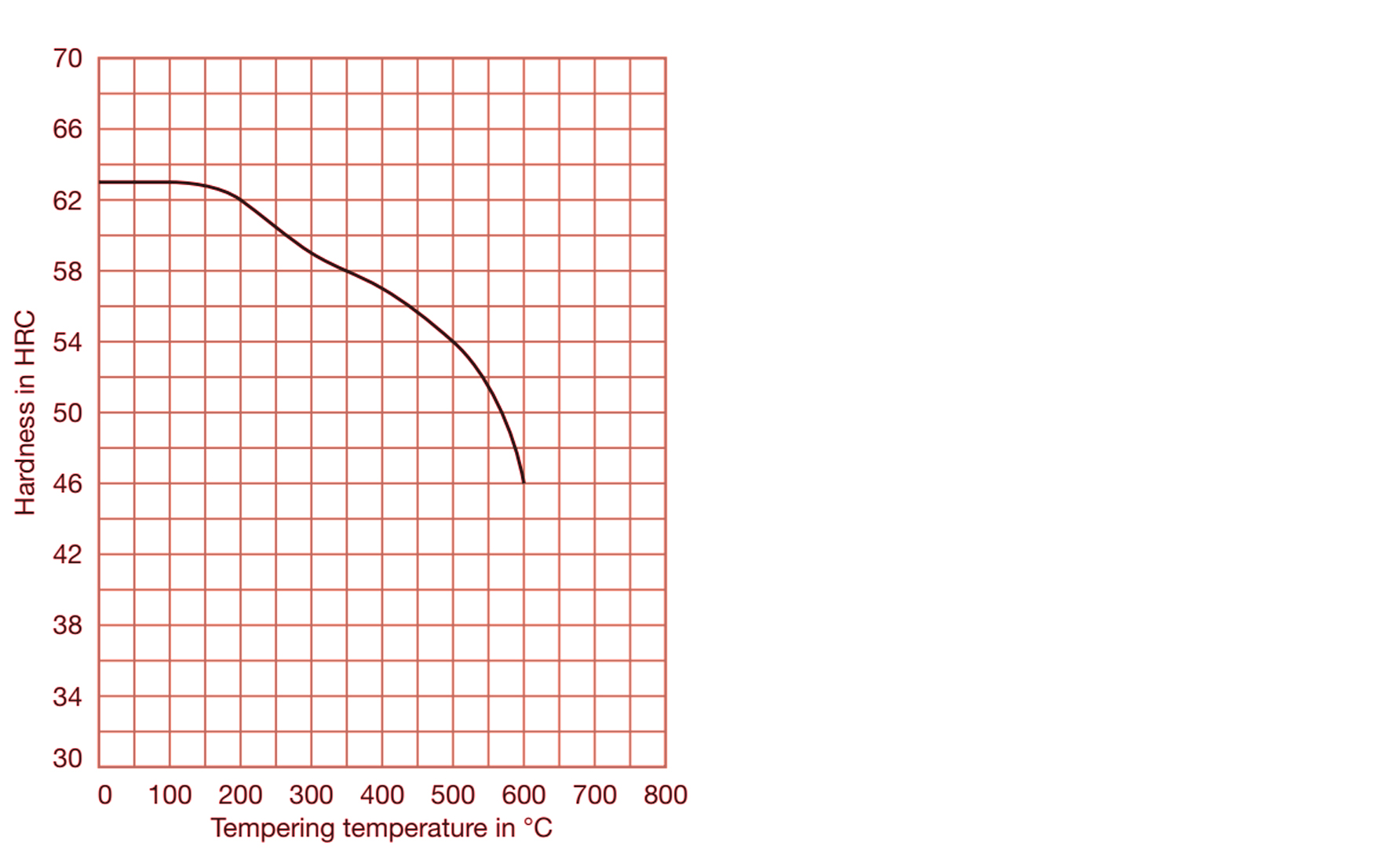

Steel properties

12 % ledeburitic chromium tool steel with extreme wear resistance.