H10/1.2365

Tool Steel

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Press and piercing mandrels, die inserts, heavy metal die casting tools. For your most challenging requirements, we recommend Thermodur 2365 EFS Superclean (ESR).

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|---|---|---|---|

| X32CrMov33 | 1.2365 | 32CDV12-28 | H-10 | SKD7 |

Chemical composition (typical; in weight %)

| C | Si | Mn | P(Max) | S(Max) | Ci | Mo | V |

|---|---|---|---|---|---|---|---|

| 028-0.35 | 0.10-0.40 | 0.15-0.45 | 0.03 | 0.03 | 2.70-3.20 | 2.50-3.00 | 0.40-0.70 |

Steel properties

- 12 % ledeburitic chromium tool steel with extreme wear resistance.

Physical properties (reference values)

| 20°C | 100°C | 200°C | 300°C | 350°C | 500°C | 600°C | |

|---|---|---|---|---|---|---|---|

| Physical properties (reference values) | 11.8 | 12.5 | 12.7 | 13.1 | 13.5 | 13.6 | 13.8 |

| Thermal conductivity at °C (W/mk) | 32.8 | - | - | - | 34.5 | - | 24.2 |

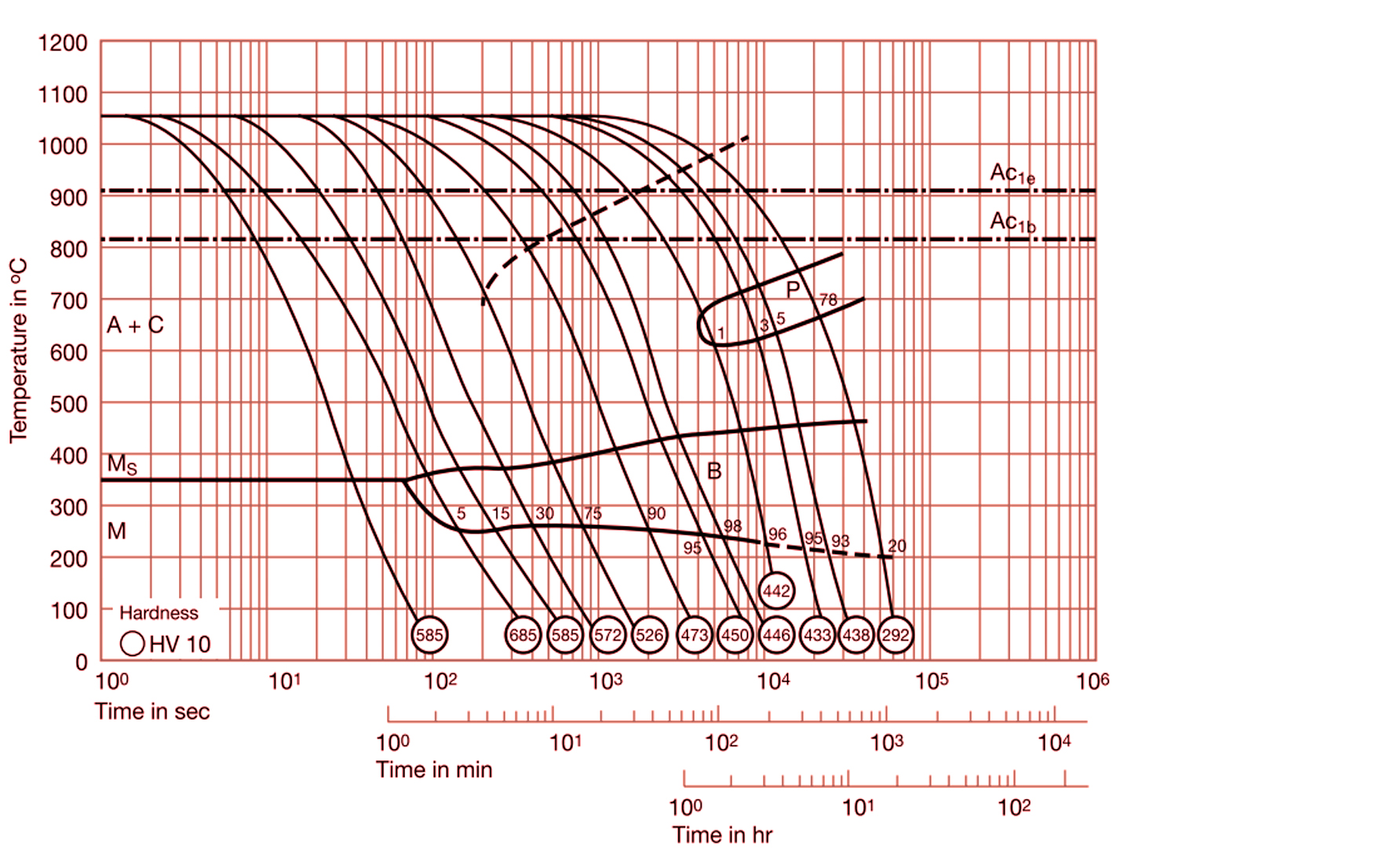

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS |

|---|---|---|---|---|

| Annealing | Heat to 750 – 800 °C | Min. H.T. for 2 minute /mm | Furnace | max. 185 |

| Hardening | Heat to 750 – 800 °C | Min. H.T. for 1 minute /mm | oil or hot bath,500 – 550 °C | 52 |

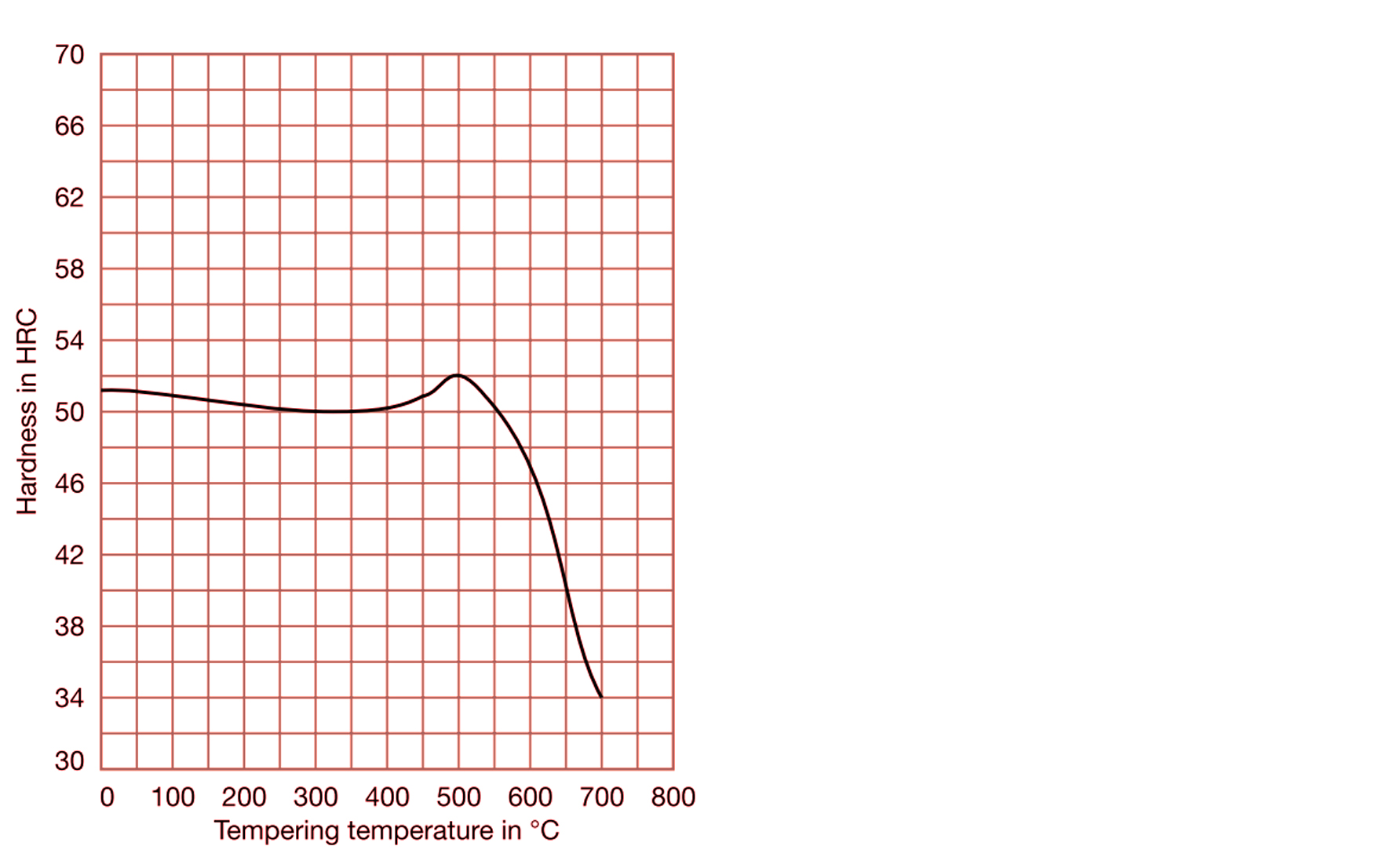

Note

| °C | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

|---|---|---|---|---|---|---|---|---|---|

| HRC | 51 | 50 | 50 | 50 | 52 | 50 | 47 | 40 | 34 |